MDA SERIES ( Heatless Desiccant )

Mikropor MDA Heatless Desiccant Air Dryers provide constant -40⁰C (-70⁰C Optional) pressure dew point.

These dryers are designed to supply clean and very dry compressed air for critical applications. Pre-filters and after-filters are standard on all Mikropor Heatless Air Dryers to keep the air stream clean and maintain the integrity of the desiccant medium. A very reliable electronic controller is utilised so the dryer operates perfectly throug its service life. MDA Heatless Desiccant Dryers are equipped with special valves and high quality desiccants in order to assure performance and provide the lowest pressure drops available in the market.

Principle of Operation

The twin tower design allows for continuous adsorption of water vapor from compressed air by using the hygroscopic desiccant with high crush strength and a high surface/volume ratio. Drying is accomplished by passing compressed air through one desiccant bed adsorbing moisture while the other is being simultaneously regenerated with the expanded purge air.

Regeneration of desiccant is accomplished without the use of heat. The wet bed is dried by diverting a small portion of the super-dry air from the outlet at near atmospheric pressure. The purge flow rate is adjustable to suit the specific outlet conditions (desired dew point). The super dry air flows in a counter direction through the wet bed, sweeping all the water vapor previously absorbed by the desiccant.

MDA ensures pressure equalization in the twin towers prior to switching.

This prevents line surge and minimizes desiccant attrition.

The tower being reactivated will be gradually re pressurized at the end of its reactivation cycle before switch over takes place.

Purge flow and de -pressurization are in downward direction, counter to the drying air flow.

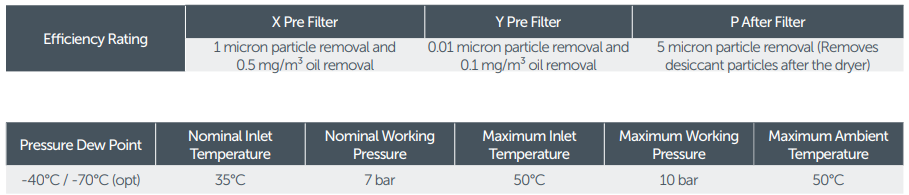

PLC is Standard

The standard controller of the series is Mini

PLC with capable of displaying PSA working parameters. The touch screen HMI, as optional controller, is capable of displaying the cycles as well as the valves as they operate in real-time. This is also capable of showing dew points. User-friendly multi-lingual HMI helps the end users understand the system’s operation and identify any issues easily.

Activated Alumina

In order to achieve consistent dew point, Mikropor uses a mixture of adsorption media in its heatless range of desiccant dryers. Activated Alumina, Molecular Sieve and Silica Gel are used in varying ratios depending on the application.

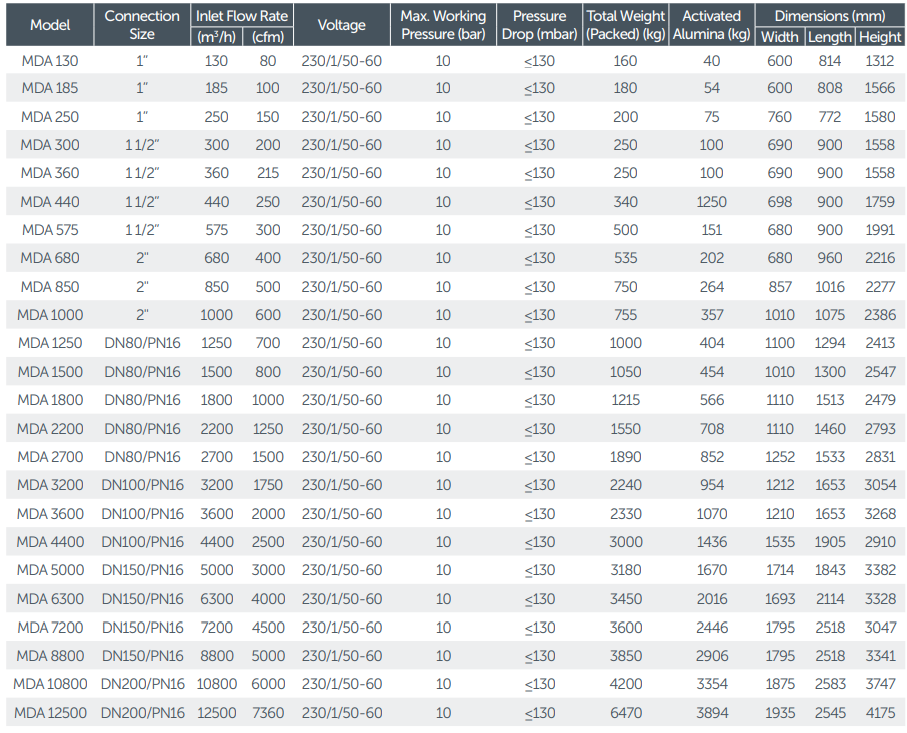

Technical Specifications