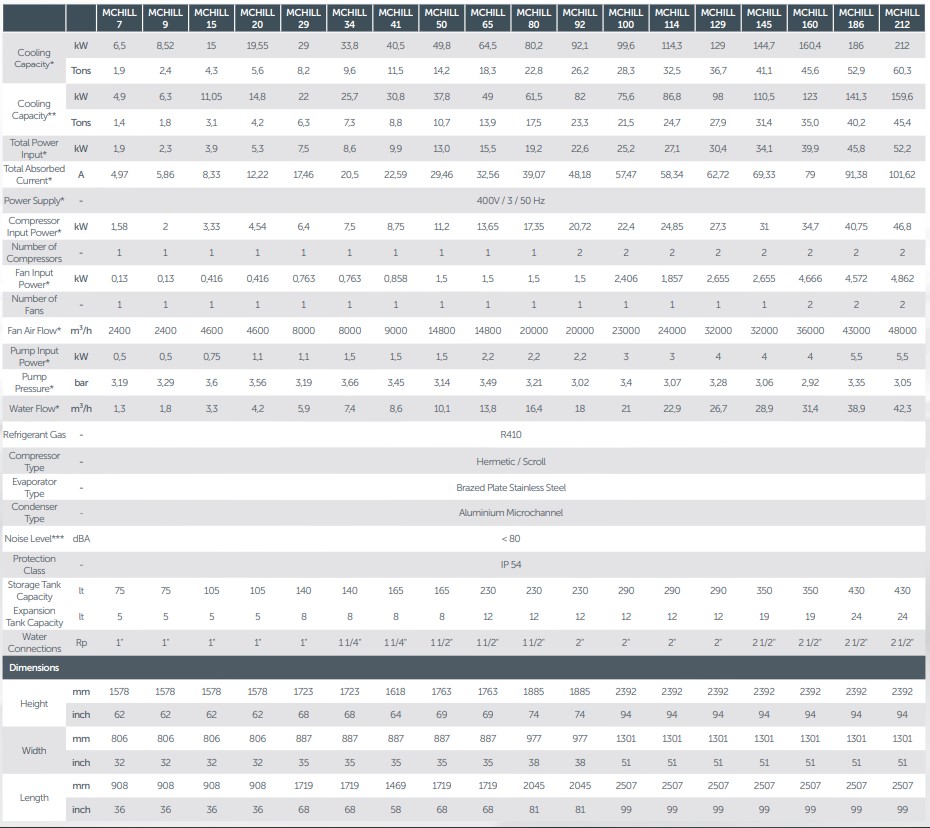

MCHILL

Easy Installation “Plug & Play”

Thanks to the design, MCHILL can be easily installed even during the ‘’process’’. The users will just need a simple pipe work and minimal labor force.

Optimizes Process Application

MCHILL Process Chillers work with a principle called “Close Circuit”. With this working principle, the following advantages can be obtained:

- Highly precise water temperature control regardless of external conditions factors

- Constant operating conditions by responding to sudden changes.

- Immediate response to sudden consumption changes quickly with closed loop and suitable pump & tank components.

- Constant use of same water – Hence, avoid waste entering the ‘’water loop system’’ and creating health problems caused by waterborne bacteria.

Best Components

All components of MCHILL (compressors, condensers, evaporators, tank, pump etc.) are ‘’Best in Class’’ and specially designed with the right equipment to consume the lowest energy.

Optimum Energy Efficiency

MCHILL is designed by a group of skilful and professional engineers to provide maximum energy savings.

- More efficiency and reduced production cycle time

- Minimized production costs and reduced waste.

- Less maintenance and downtime during production.

Optimum Energy Efficiency

Unlike typical water chillers for processes that have been used for many years, the MCHILL unit is designed to meet the user’s need in the simplest way with minimum operating costs and best performance.

- Wide operating conditions related to both inlet and outlet water temperature.

- Thanks to the “Global Design”, the MCHILL can even operate in the highest ambient temperature conditions around the world.

- A wide range of optional accessories that allow MCHILL to be customized for various special applications.

- A fully packaged and easy-to-use solution with integrated pumps, tanks and safety systems which make it perfectly suitable to the needs of industrial processes.

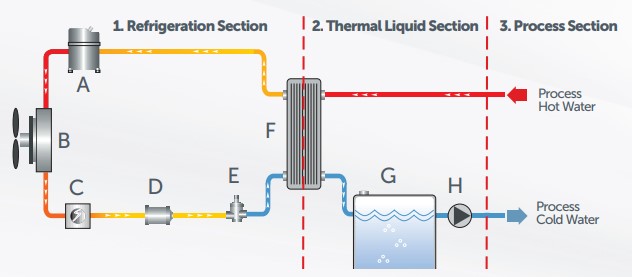

The MCHILL Process Chillers includes 3 sections:

A – Compressor

B – Condenser

C – Sight Glass

D- Filter Dryer

E – Expansion Valve

F – Brazed Plate Heat Exchanger

(Refrigerant Gas to Thermal Liquid)

G- Storage Tank

H- Chiller Water Pump

How it works?

As illustrated in the picture, the Thermal Liquid loop section operates as a closed circuit. The generated cold water is delivered to the application of the user’s process by the water pump in MCHILL. Once the cooling is completed, the cold water gets heated up and returns to MCHILL in higher temperatures. Thereafter, the process water keeps on circulating through the pressurized system in the same manner.

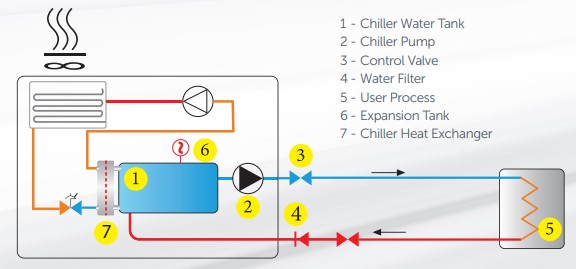

Water System - Equipment and Process

Closed Circuit Process

1 – Chiller Water Tank

2 – Chiller Pump

3 – Control Valve

4 – Water Filter

5 – User Process

6 – Expansion Tank

7 – Chiller Heat Exchanger

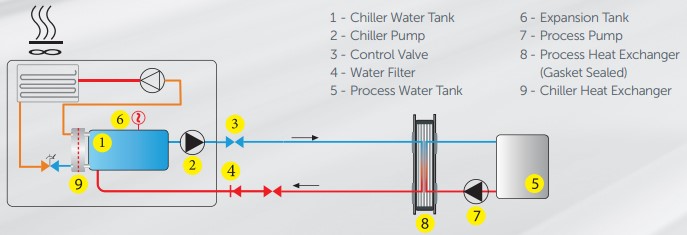

Open Circuit Process (Optional)

1 – Chiller Water Tank

2 – Chiller Pump

3 – Control Valve

4 – Water Filter

5 – Process Water Tank

6 – Expansion Tank

7 – Process Pump

8- Process Heat Exchanger (Gasket Sealed)

9 – Chiller Heat Exchanger

Refrigerant Circuit - Main Components

Refrigerant Scroll Compressors

R410A REFRIGERANT

- Leading Refrigerant Compressors Brands

- Hermetic Scroll Compressor

- Durable and Long-Life Compressor Models

- Single or Multiple Compressor Operation

- Environment Friendly R410A Refrigerant Gas

- High Thermodynamic Properties

- Environmentally Considerate

New Technology, Aluminium Microchannel Refrigerant Condenser

- Less energy Loss with Low Pressure Drop

- High Heat Transfer Capacity

- Surface Coating Against Corrosive Environments

- Less Amount of Refrigerant Gas

- Resistant to any galvanic reaction and Corrosion

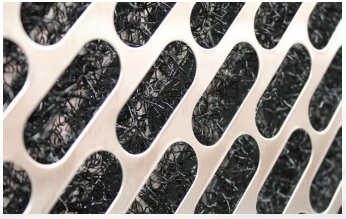

Cleanable Condenser Pre-Filters

To protect the condensers all MCHILL chillers include progressive composite fiber mesh filters which can be easily removed for service and cleaning. Stainless steel frame avoids corrosion even when the filter is washed with water or other washing fluids.

EC Fan Motor-Variable Speed Motor

- Leading Fan Motor Brands

- EC - Variable Speed Fan Motor

- Durable and Long-Life Fan Motor Models

- Lower Energy Consumption

- Low Noise Level

Evaporator

- Brazed Plate Stainless Steel

- Extremely Efficient

- High Heat Transfer Surface Area

- Compact Size

- Independent Installed

Refrigerant Circuit - Main Components

Protection of the Evaporator

Thermostatic Expansion Valve

- Electronic Control for Anti-Freeze

- A Differential Pressure Switch for No or Lower Water Flow

- A Mechanical Water Filter

- Leading Refrigerant Valve Brands

- More Stable and High Cooling Performance

Water Circuit - Main Components

Expansion Tank

Integrated Cold Storage Tank

MCHILL cold water storage tank is heat insulated and made of carbon steel material. The following equipment are also provided together with the storage tank in the MCHILL system.

Pressurised

When cooling water temperature increases the water expands. In order not to increase the pressure an expansion tank is used on the water storage tank.

Atmospheric

Atmospheric Expansion Tank is also available for open circuits as an option.

- Expansion Tank

- Inlet-Outlet Manual Valve

- Safety Valve

- Automatic Venting Valve

- Level Sensor

- Water Filter

- Drain Valve

- Water Pressure Gauge

Integrated Water Pump - 3 bar

- Stainless Steel Body

- Special Seals for Process Fluids

- High Capacity Centrifugal Pump

- Long Lasting Centrifugal Pump

- Maintenance-Free Operation

- High Efficiency-Stainless Steel Impeller

For maximum control

The large water storage tank is placed right after the heat exchanger water outlet to limit the temperature fluctuations during the sudden load changes. The tank’s generous dimensions ensure stable water temperatures.

For Sudden Consumption

Large liquid storage tank provides constant and precise liquid outlet temperature even at sudden consumptions.

For Energy Efficiency

Cold water storage tank and cooling capacity of the system are directly associated with each other. When developing the MCHILL, Mikropor’s professional engineers have utilized these parameters to provide maximum energy savings by minimizing switch on/off rates of compressors.

For System Protection

Volumetric changes in the system are compensated by the control equipment in the system. Thus, the constant cold-water circulation occurs smoothly in the

process circuit.

Control and Safety Groups - Main Components

Electronic Controller

All MCHILL models have a standard microprocessor which offers;

- Ease of Use

- Precise Control

- Reliable Operation

- Remote Control

- Free Cooling Control

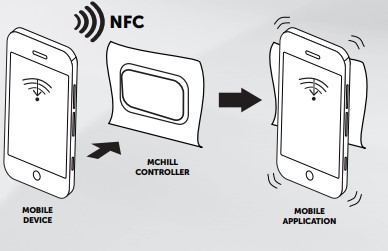

- NFC via Mobile Device

- High Quality Microprocessor Controller

- High Efficient Control Algorithm

- User Interface On Graphic Terminal

- Compact Size

- Interaction With Mobile Devices

APPLICA

MCHILL controller supports remote communication. All data can be monitored, saved and changed by using APPLICA mobile application through NFC while being near the MCHILL controller. APPLICA can be used on any device that can be connected to the internet.

“MCHILL Application” can be used to configure the controller on a mobile device (smartphone, tablet), by NFC (Near Field Communication). Users can both configure the commissioning parameters and set groups of preset parameters according to their own particular needs.

Additionally, it supports Modbus communication. Thanks to the pins on the J4 BMS port, communication between the controller and SCADA system can be established. The device supporting the Modbus RS485 communication protocol can be used with more than one slave. BMS settings can be controlled both on the screen and on APPLICA.

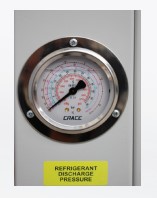

Refrigerant Gas Pressure Gauges

All MCHILL models have a standard refrigerant gas high and low-pressure gauges.

Temperature and Pressure Sensors

In MCHILL systems, pressure and chilling temperatures are measured electronically. The measured data is processed continuously by Microprocess Controller to ensure the safest and most efficient operating conditions within the system. Moreover, the temperature or pressure of both high and low-pressure manifolds and water in the storage tank can also be constantly measured along the system’s cooling section.

Together with the standard features, Mikropor also offers the following options for the cold water loop system of MCHILL to provide decent and higher quality cold water when requested by users alternatively.

These features are not avaible in all sizes. For more information, do not hesitate to contact Mikropor Sales Team.

Process Evaporator Option

- High efficiency, low energy loss

- Easy to install

- External heat exchanger specially recommended for processes delivering dirt from the process to the water chiller

- External water pump to be used with external heat exchanger

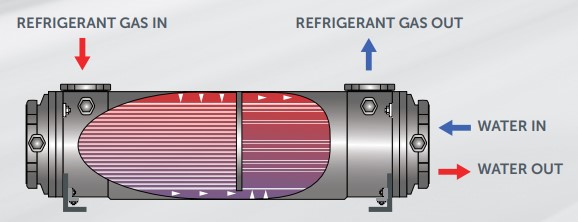

Water Cooled Option

In some cases or applications where air-cooled models cannot be used or where warm water supply is required, MCHILL offers water-cooled models that include a Water Cooled Condenser and a Presostatic Water Control Valve.

Special Water Pump Option

3 bar water pump is supplied as a standard unit, but in some applications more pressurized cooled water may be required. In these cases, a 5 bar water pump can be offered as an option.

Other Option Features

- Atmospheric Pressure Kit Option

- Low Ambient Temperature Option

- High Corrosive Environments Option

- Non Ferrous Design Option

- Heater For Storage Tank Option

- Automatic Filling Kit Option