MTD

Water in the pneumatic system can be problematic. While the air is compressed the moisture inside the air is also densified and this remaining water damages the system components in time. For that reason, compressed air treatments have been used for a very long time.

Mikropor brings an innovative approach to compressed air drying systems by producing Mikropor Turbo Dryer (MTD) units. It is tremendously effective to use this unit in the high- capacity drying process which is in the range of 10.000 Nm³/h – 30.000 Nm³/h.

The large capacity drying system is often problematic and very expensive due to the lack of available space in the equipment room. Mikropor solved these problems with its new compact design of

MTD series. In MTD series all components are placed in one unit. Even in a very large capacity compressed air system 3°C dew point achieved. In addition, with used thermal mass technology drying process can be done with energy-saving even in the fluctuating compressed air usage.

Working Principle

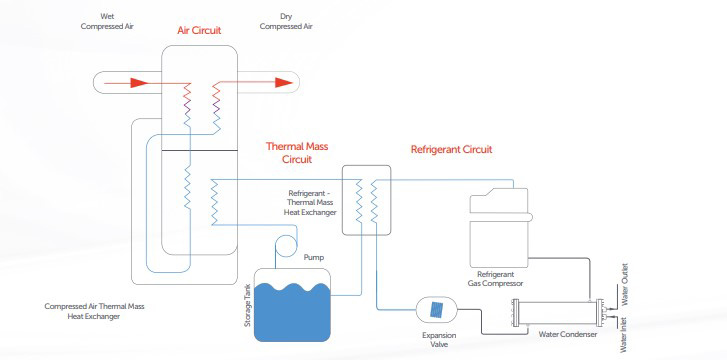

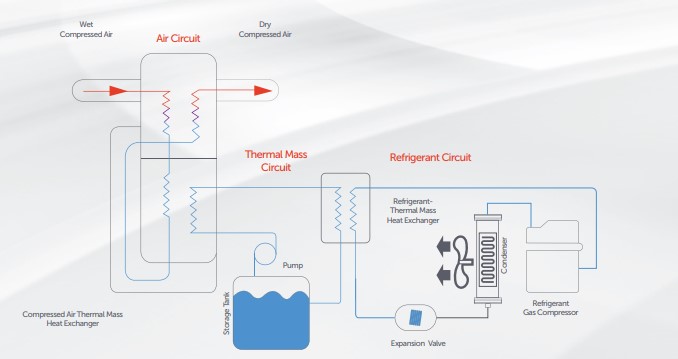

Wet compressed air enters the 3 in 1 aluminum heat exchangers. In the beginning, the wet compressed air, is pre-cooled by coming counter-current dried air in the air-to-air part of the heat exchanger. Then it comes across with the thermal mass to decrease the dew point up to 3°C with the bottom of the heat exchanger condensate water droplets are collected and drained. Heated thermal mass gets colder with cold refrigerant gas and send to the heat exchanger again. This circulation continued to sustain dry compressed air in the system.

Standard Features

- 7” Touch Screen (MTD 25000 - 30000) 4,3” Touch Screen (MTD 10000 - 20000)

- Standard Modbus RS485 Communication

- High Strength Aluminium Design 3in 1 Heat Exchanger

- High Efficiency Scroll (MTD 10000 - 20000) and Screw (25000 - 30000) Refrigerant Compressor

- Stable Dew Point with Thermal Mass Technology

- Stainless Steel Cooling Components Mass-Refrigerant Evaporator, Pump

- Compact Design

- 10 barg Maximum Working Pressure

- Water Cooled Condenser

Optional Features

- Air-Cooled Condenser

- IP Communication with pCoWEB

- WebServer Feature

- BACNET, SNMP, MODBUS TCP/IP Communication

MTD Unit – Water Condenser

MTD Unit – Air Cooled

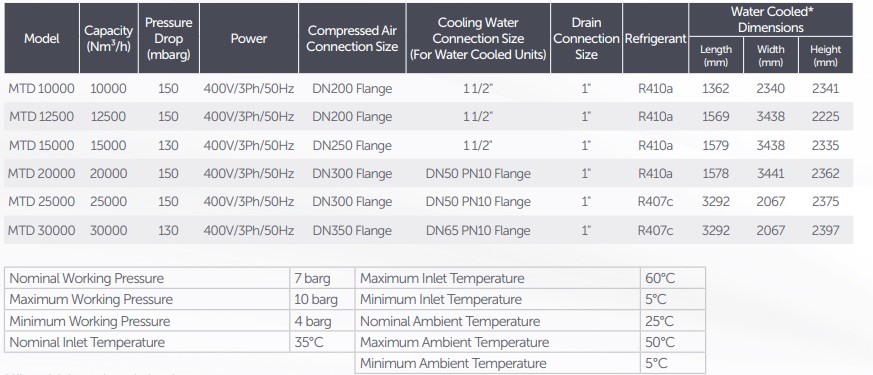

MTD Series - Technical Specifications