MSF SERIES

Mikropor Sterile Filter Housing

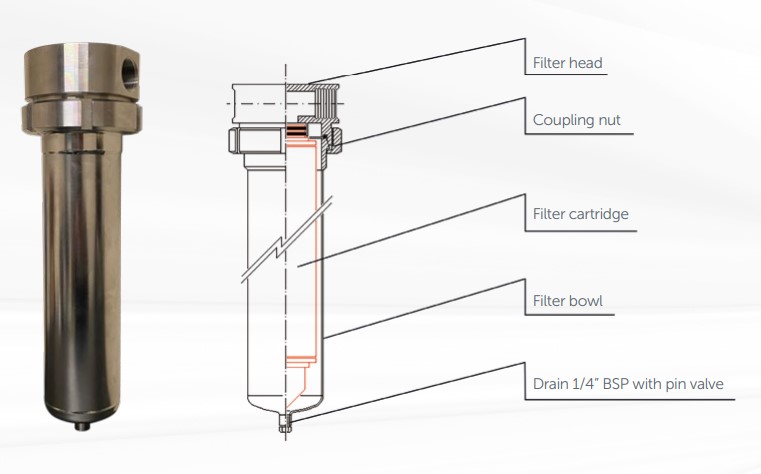

MSF is a high-quality filter housing to provide safety and reliability in desired conditions. As the coupling body-bowl is designed to prevent unscrewing when in pressure, they are suitable in

compressed air and gases.

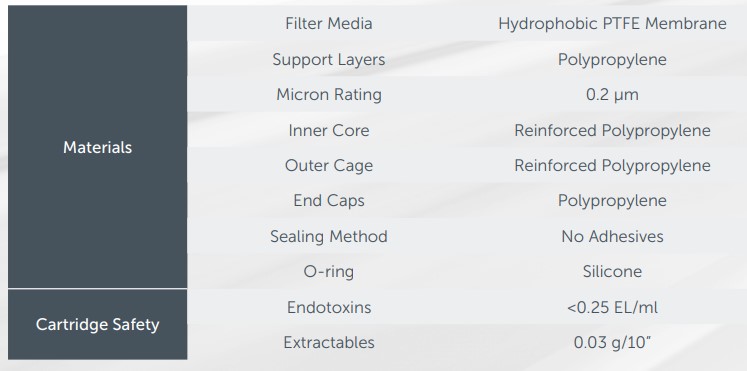

Mikropor PTFE Sterile Element

The MSF PTFE Membrane Filter offers 99.99% absolute filtration efficiency with a naturally hydrophobic PTFE membrane featuring high porosity and flow rate. This filter stands out with its low-pressure drop and long service life, while demonstrating broad chemical compatibility against strong alkalis, acids, and aggressive gases, and maintaining high temperature resistance.

The MSF Membrane Series is available in 0.20 µm pore size.

Working Principle

The purpose of sterile filters in compressed air systems is to prevent the passage of microorganisms in compressed air and gases. These filters consist of a membrane structure with micro-pores. They effectively filter out more than 99.99%. To maintain flow rate and prevent accumulation on the filter surface during filtration, regular inspection and sterilization of the filters

are required. Sterile filters are widely used in areas such as pharmaceutical production, biotechnology, food, and beverage production, medical device sterilization, and laboratory applications.

Sterilization

There are two types of sterilization process, both for preventing bacterial contamination by sterilizing filter elements and housings. It ensures filtration efficiency, extends filter lifespan,

and maintains sterility in critical industries like food, beverage, and pharmaceuticals. This process guarantees product safety and regulatory compliance through efficient steam sterilization. These sterilization types are stated below including necessary steps.

1)Sterilization-in-Place

The process is introduced step-by-step below and the parameters are in the table below.

- Ensure the filter housing and element are in place

- All system connections except for steam inlet and condensate drain shall be closed

- Filtered steam (min. 1 bar) is supplied

- The required sterilization temperature (121-141°C) is maintained

- Steam for 10-30 minutes, depending on temperature shall be flowing constantly

- The condensate to prevent cold spots shall be drained continuously

- After sterilization process, sterile air or gas to cool the system shall be introduced

- The system integrity shall be checked (any leaks, etc.)

- The filter is now sterile and ready for use

2) Autoclave

The other sterilization process option is the autoclave. The elements can be sterilized by this process. The process is introduced step-by-step below and the parameters are in the table below.

- The filter element and housing remain in place and steam is used to sterilize the filtration system without the need for removing

- The steam shall be free of rust and other particles

- Steam pressure shall not be allowed to fall below 1 bar or 121°C throughout the sterilization process

- Any air trapped in the housing shall be vented. The condensate shall be drained from the system during sterilization. Discharge the remaining air by loosening the drain on the bottom of the filter using a wrench

- After sterilization pressurize the system with process air or gas up the stream pressure used and allow the system to cool until ready for use

- Gently tighten the drain relief valve by using a wrench as shown below

NOTE: Generally, the only filter element is sterilized in an autoclave, but both the housing and element can be sterilized if removed from the process disassembled and put in the autoclave.

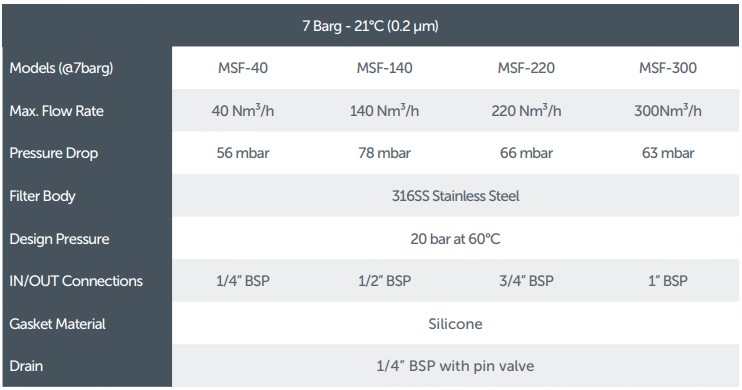

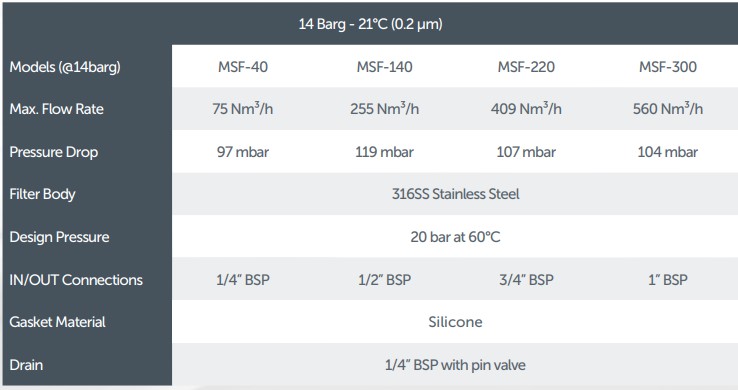

Specifications

Main Applications

- Various process filtrations

- Compressed air and gases filtration

- Sterile compressed air and gas filtration

- Food and beverage production

- Pharmaceutical production

- Biotechnology

- Medical device sterilization

- Laboratory applications

- Any need in sterile filtration application

Features and Benefits

- Hydrophobic PTFE Membrane with superior porosity

- Long service life

- Filtration efficiency ≥99.99%

- Wide chemical compatibility, resistant to strong gases and solvents

- Low pressure drop

- High temperature performance

- Specifically designed to ensure sterilization

- Filter head offers a smooth surface preventing bacteria growth

- Heavy duty construction for housing

- Filter bowl with minimum seams

- Four different cartridge lengths to a maximum of 2 m² of filter area

- The head-bowl coupling uses a threaded round nut for secure fastening under pressure, ensuring greater reliability than clamped systems