MKE SERIES ( Non Cycling)

Mikropor is aware of the importance of high quality compressed air and guarantees to provide customers with the highest quality of air. Using clean, dry air is extremely important for all kinds of air powered applications. Moisture or contamination in the air which will come from the standard compressor outlet will cause complicated system errors. These complications will decrease productivity and may affect the production quality of final products

Advantages

- Low pressure drop saves compressor power

- Quick start and reaction time provides additional production time

- Every dryer is specially designed with the right components to consume the lowest energy

- Highly energy efficient and environmentally friendly R513a refrigerant across all models.

- R513a refrigerant is optional.

- A state-of-the-art heat exchanger design provides the highest cost saving in the industry

- Best in class refrigerant compressors consume less energy against competition dryers

- Pressure switches control the condenser’s fan motor for saving energy and letting the system operate at desired conditions

- This is not only a dryer, but an air treatment package that delivers an air quality of class 1.4.1 as per ISO 8573:2010 due to integrated filtration

Applications

Mikropor provides an entire range of products for filtration and air purification applications at a cost effective price.

Applications Include

- Food production, dairies, breweries, clean conveying air, chemical plants, pure air and cleanroom technology, pharmaceutical industry, weaving machines, photo labs, paint spraying, powder coating, packaging, control and instrument air, sand and/or shot blasting, general air works, microchip production, optics, process air as well as many other markets

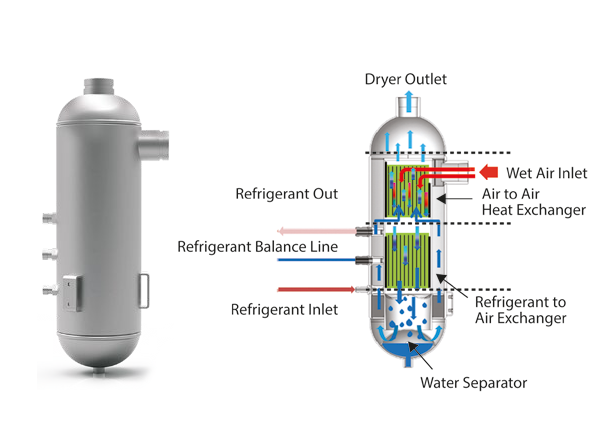

The MKE Series Refrigerant Circuit and Insulation

Mikropor only uses environmentally friendly R513a refrigerant gas in the dryers. This refrigerant is suitable for both low and high temperature applications. R513a has excellent thermodynamic properties and can operate at very low pressure compared to other refrigerants. This will in turn increase the refrigerant compressor’s service life. With R513a Mikropor dryers can operate at very high ambient temperatures. Mikropor engineers add extra power to the heat exchangers with excellent and extraordinary no loss insulation system. Mikropor dryers supply constant dew point at all flow ranges. This perfect insulation idea continues on the refrigeration circuit side as well. With this insulation concept and oversized condensers (Even for ultra high ambient temperatures) Mikropor Refrigerated Air Dryers offer the highest technology with its custom solutions.

Digital Controllers

Digi-Pro digital controller is standard on MKE23-MKE3915

ESD digital controller is standard on MKE5085-MKE12500

Digi-Pro Digital Controller

Mikropor now produces a new generation of air dryers with Digi-Pro series controllers. With the Digi Pro series controllers, air dryers have outstanding technology for both functionality and dynamism, as well as appearance. New controller design offers users the possibility of making adjustments with one finger, thus easier accessibility. The touch keys have taken the design and dynamism to a top level of technology. The multi-functional display provides an accurate digital dew point display as well as coded alarm monitoring of the refrigerant dryer.

Digital controller with embedded features,

- Digital dew point monitoring

- Energy-saving mode display

- Periodic maintenance interval display

- Status report

- Hours run meter

- Fahrenheit and Centigrade selection

ESD Digital Controller

Mikropor Refrigerated Air dryers with ESD Digital controller have a lot of economy features and alarm capabilities. Refrigeration dryers are usually the most efficient dryer solution for the compressed air applications.

With the help of the highly engineered ESD, Mikropor Refrigerated Air Dryers will reduce your energy consumption. ESD helps the service technicians to monitor many useful parameters on the dryer and guides them to troubleshoot any problem very easily. ESD is extremely useful when there is no air coming into the dryer when the dryer is running. Especially during the nights, weekends and holidays many companies do not stop their dryers although they do not run compressed air. ESD saves huge amount of money by simply shutting the dryer down automatically when it is not in use.

Electrical Wires are Separated From Refrigerant Side

There are very few electrical wires inside the refrigerant side of the dryer. Electrical box has an external cover with access from the outside of the dryer. Therefore there is no need to open dryer panels electrical access.

Compact Design

Mikropor dryers are highly reliable, efficient and have small space demands and offer low cost ownership.

Mikropor Refrigerated Air Dryers are suitable for the smallest installation spaces. Having two filters integrated into the dryer frame offers a huge advantage to the service technicians and end users. The integrated filters save labor time, piping cost and space at the facilities where the Mikropor Dryer is used. The compact size also offers flexibility and economy during their transport.

Aluminium Plate Heat Exchanger is Standard

- Very low pressure drop

- Thin aluminium plate thickness

- High heat transfer surface area

- Strong due to external thick cylindrical wall

- Water separator is optimized for best performance

Scroll Compressors

Scroll Compressors are energy efficient and strong against liquid shocks. For energy saving, scroll compressors are used for 400 m³/h and above MKE Dryers.

Easy Access

Easy access to the cooling components in seconds by the help of screw free panels and plastic handless. Easy for service and offers more working space. Service technicians save time by not having to remove fasteners.

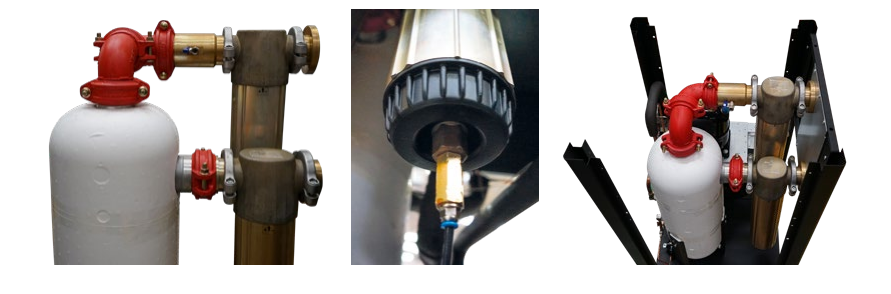

Zero Clearance Compressed Air Filters with High Performance Elements

Compressed Air Filter kit is standard on the Mikropor Dryers. The filter with X Element (coalescing filter for water removal) is used for up to 1 micron particles and the Filter with Y Element (coalescing filter for oil removal) is used to remove oil down to 0.01 ppm. Zero clearance

design helps service technicians to replace the element in minutes.

Mikropor Refrigerated Air Dryers are designed by engineers who have received all of the design feedback from field engineers and service technicians. This service friendly design makes Mikropor dryers very unique in the industry. Dryer Filter kit which has two elements, two viton o-rings helps the customers to operate the dryer at its best performance until the next planned maintenance.

Grooved Couplings and Fittings

On compressed air lines, grooved couplings and fittings are commonly used in the industry. These couplings increase flexibility on connections, help the service technician to dismantle and assemble pipes easily and quickly.

Excessive Water Droplet Drains

Liquid water droplets coming from the line to the inlet of the dryer are separated by the inlet filter and drained. The automatic timer drain can be open manually. This allows the system to be depressurized at maintenance service.

Replacement Filter Element

Pressure drop is a huge concern in compressed air. In many applications high pressure drops will cause a decrease in the pressure at the point of use. Sometimes this low pressure is not enough for the machines or processes to perform correctly. In addition, dirt particles and oil in the compressed air system may block the filters quickly. It is important for the end users and service technicians to recognize if there is a problem in the system. The performance of the filters directly affects the pressure drop and system performance. Therefore, it is very important that the filter elements are changed at the filter service time. An alarm/warning indicating that the filters are changed periodically is provided by a digital controller on the Mikropor Air Dryer. When this alarm triggers, the filter must be changed to avoid loss of performance and pressure drop.

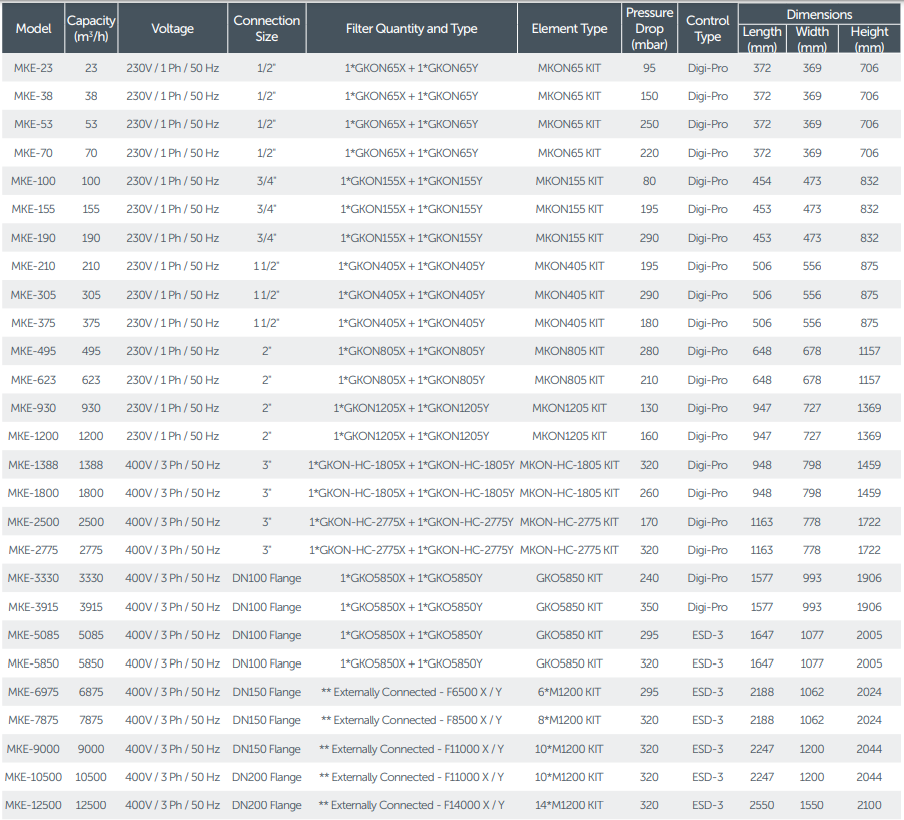

Technical Specifications