CARBOLESCER

There are contaminant effects that could be contained within the compressed air such as oil, water, and particles. This causes damage to compressed air system lines, pneumatic systems and equipment. The main reason is high oil and water content in compressed air systems. The ambient air is compressed by 7 times in order to achieve the desired pressure value and it gets down into smaller volumes. That means if the pressure is higher when the air is compressed, the concentration gets higher. Therefore compressors produce almost 7 times more oil or watercontaining air than atmospheric air. In addition to these contaminants, oil can also enter the compressed ai system through the ambient air even if it is oil-free. Oil is carried by the compressed air in two forms: as an aerosol that is formed by the mechanical shearing in the compressor, and also as a vapor that is formed during the oil vaporization and compressor intake air. These oil forms have to be prevented in order to increase the product quality and pneumatic equipment lifespan. The main working principle for the separation of these oil contents is about coalescing of the aerosol form by filter and separator and is about adsorption of the vapor form by desiccants.

There are some filters to remove liquid oil. However, an aerosol form of the oil can not be separated from those filters. Mikropor’s patented product Carbolescer can remove both forms of the oil. Carbolescer is a combination of a mist

eliminator and a media impregnated activated carbon. It has plated coalescing media, carbon layer, and wrapped particulate media. Liquid formed oil is eliminated with the coalescing method in the plated media. As oil-flooded compressed air enters the unit, oil droplets accumulate and fall through the filter media. Collected liquid oil is drained from the egg drain. With plated coalescing media 0.01-micron-sized oil contaminants can be removed.

In addition to the plated media, the activated carbon layer is adsorbed the oil vapor. Oil vapor adheres physically through the active carbon media and in that way, the remaining oil content can be decreased to 0.003 ppm. Then, the layer of particulate media helps to remove particles that possible to remained. Finally, oil-free compressed air can be achieved even after the screw compressors that is “Class 0” according to ISO 8573 standard.

Standard Features

- Very low-pressure drops (80 mbar)

- Maximum remaining oil aerosol content 0.003 ppm

- Equal air distribution

- Long service life

- User-friendly changing procedure

Optional Feature

- Oil indicator

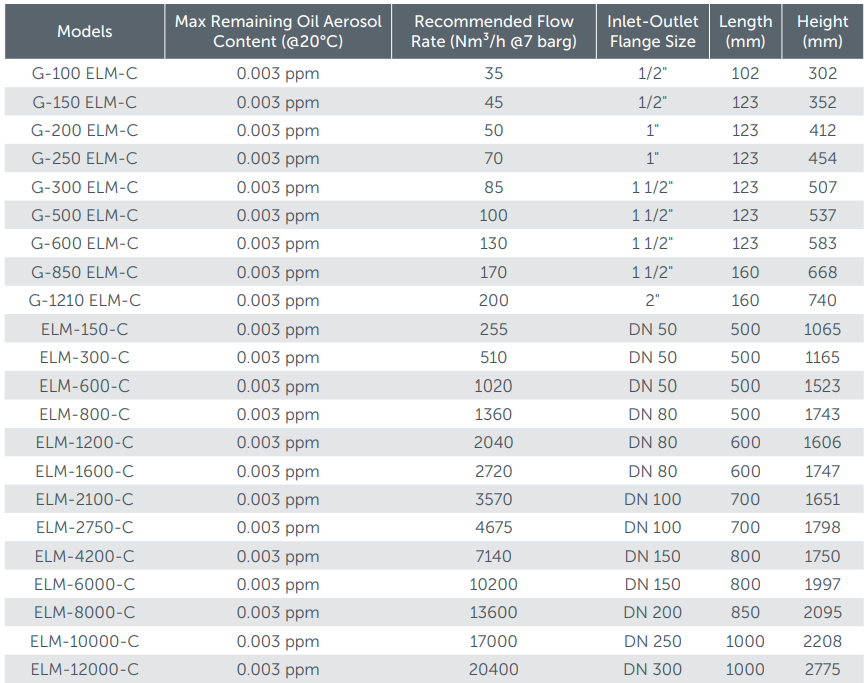

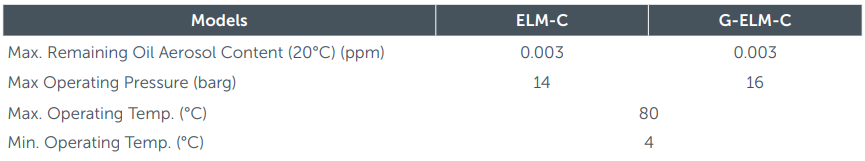

Technical Specification