15-20 Bar Compressor Series

Fast, Cost-Effective and Competitive Solutions for Laser Cutting

Unleash uninterrupted laser cutting capabilities with Ozen’s 15-20 Bar efficient compressors. As a crucial component in laser cutting operations, air compressors serve as the primary gas source, ensuring a seamless cutting process. Depending on the material and thickness, compressed air can achieve faster cutting rates and enhance overall productivity. By using compressed air for laser cutting, businesses can eliminate the downtime associated with changing nitrogen cylinders, leading to accelerated cutting processes and heightened productivity levels. Transitioning to air assist cutting is straightforward and cost-effective, even for older laser cutting models, making it a practical choice for businesses seeking enhanced efficiency .

1) Compact Oil Separator Design

- CE approved tank

- Spin-on filter components

- Minimum pressure drop

- Oil level control

2) Maestro

- User-friendly control panel indicators facilitate the assessment of the equipment as well as the planning of maintenance

- Support for 10 languages

- Oil level control

3) Symmetrical Cooling System

- Guaranteed cooling performance with large size radiator pack

- Strong, compact design provides durability that is tested and proven under tough work conditions.

- Enables your compressor to keep working with high efficiency under various climate conditions

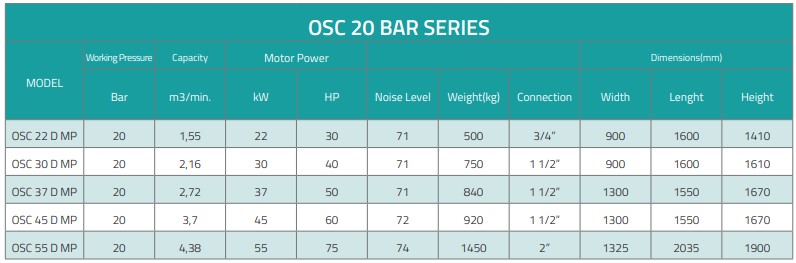

Technical data: